Description

Product Introduction

The non-ferrous metal eddy current separator consists of a magnetic roller,a conveyor belt, a driving roller,a main frame and other parts. The high-speed rotation of the magnetic roller generates a high-frequency alternating magnetic field,which can induce eddy currents inside non-ferrous metals. The magnetic field generated by this eddy current is opposite to the original magnetic field.The non-ferrous metals will jump out along the conveyor belt due to the opposite force, achieving the purpose of separation.

Application Field

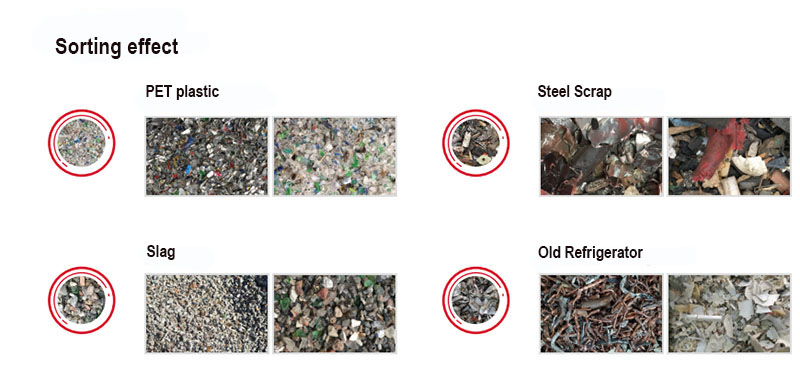

The eddy current separator is mainly suitable for sorting non-ferrous metals such as copper and aluminum from industrial waste and domestic waste for more fine sorting occasions.

It can be widely used in garbage disposal, scrap car dismantling and recycling, waste electrical appliances recycling and other fields, as well as non-ferrous metal processing industry material treatment and other industries.

Product Specifiticities

1. Eccentric magnetic roller design: effectively prevent magnetic particles from entering between the magnetic roller and the belt to avoid scratching the belt;

2. Leading non-leakage magnetic system design: ensure higher metal recovery rate;

3. Unique belt inclination design: effectively prevent non-ferrous metal rebound and improve metal recovery rate;

4. Intelligent centralized lubrication system: automatically set the oil filling cycle to ensure long-term stable operation of each bearing;

5. Comprehensive safety guarantee: installed monitoring and alarm system to monitor the operation of each key component in real time;

6. Intelligent touch control system: the equipment starts with one button and is easy to operate; it can provide real-time feedback on key components and operating parameters;

7. Select SEW motors imported from Germany, which are stable and reliable with low noise;

8. Select SKF bearings imported from Sweden, which have long service life and low noise;

9. Select high-quality German Siegling belts, which are durable.